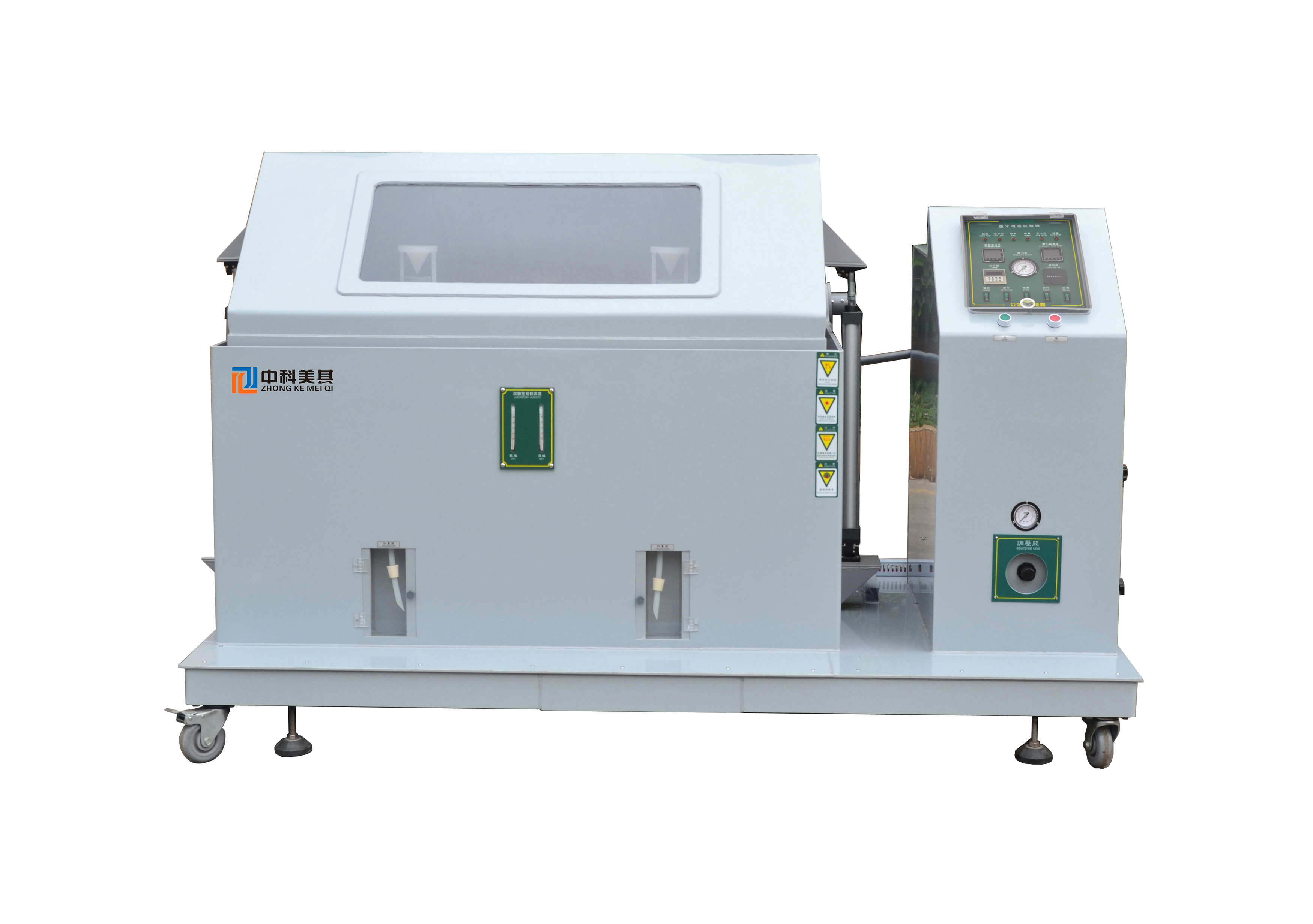

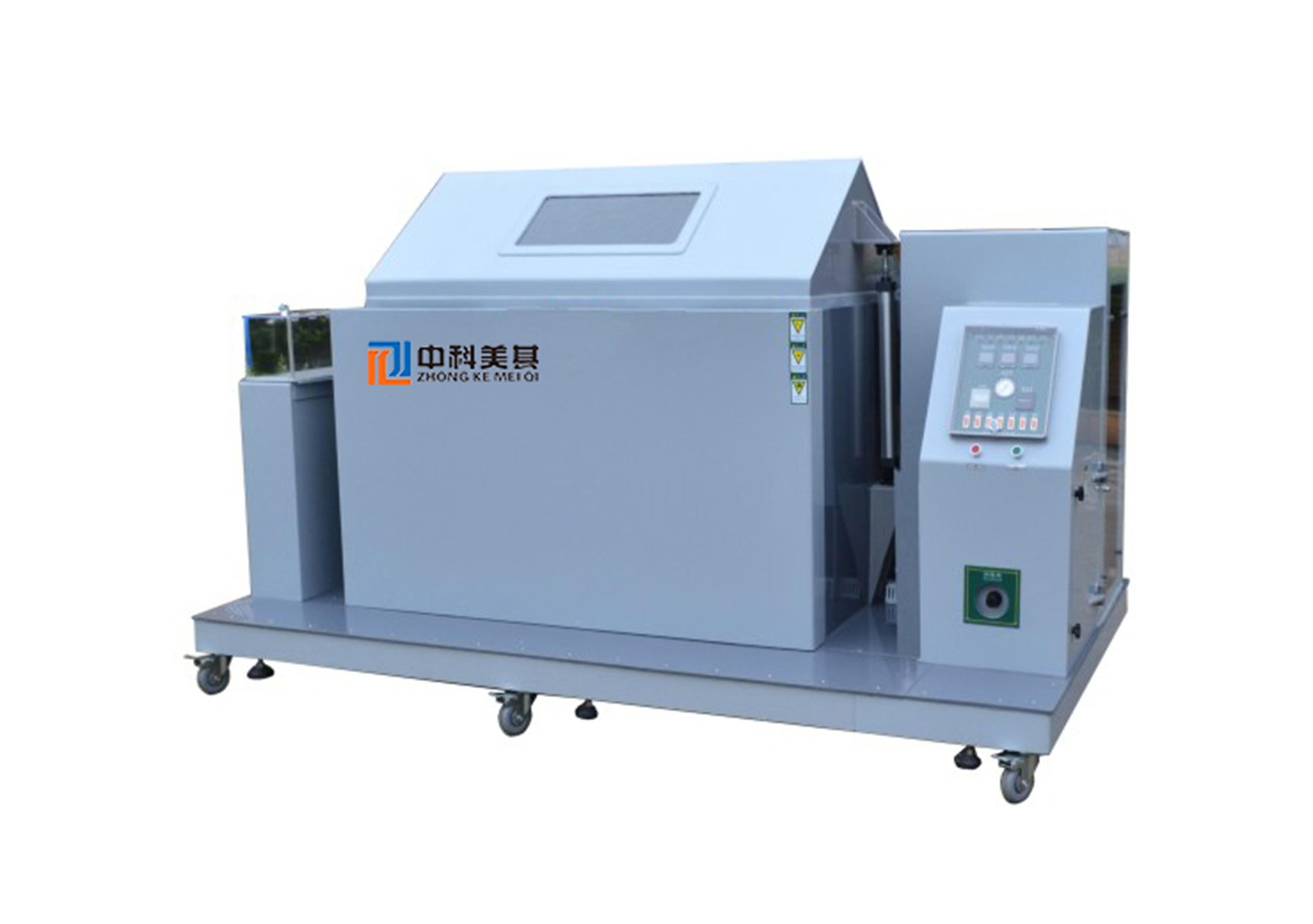

Model:MQ-FHYW-160

Compound-type Salt Spray Test Chamber with Humidity

Product Features:

Two-pole intake and decompression to ensure stable spray pressure

The high-precision imported touch screen temperature and humidity special intelligent controller realizes effective control of temperature, humidity, drying and salt water spraying.

Spray tower top cone disperser with salt spray guidance and adjustment of salt spray uniformity and its settlement.

Perfect protection function (water shortage, super-wet, overload, etc.) and the device has the function of voice, alarm and stop.

The spray is compressed with compressed air to ensure stable test environment conditions and effectively prevent nozzle clogging.

It is equipped with a device running time controller, which automatically shuts down after the running time is completed.

The inner and outer gallbladders of the studio are made of anti-corrosion materials, featuring light weight, high strength, no leakage, smooth surface, smooth and easy to clean.

The water seal salt spray does not leak, and the jacket air duct heats up, so that the temperature rises in the studio and the temperature distribution is even.

Tower spray, the material is small, and the salt spray is naturally distributed evenly.

Compound-type Salt Spray Test Chamber with Humidity

Standard Compliance :

1)GB/T2423.17-2008/IEC 60068-2-11 Test method for salt spray

2)ASTM.B117-2009 Test method for salt spray

3)JIS H8502 Test method for saline spray

4)GB/T10125-2012/ISO 9227-2006 Test method for saline spray

5)GB-T5170.8-2008 Test method for environmental test equipment for electrical and electronic products - salt spray test equipment

6)GB-T5170.11-2008 Test method for corrosive gas test equipment

7)GB-T10587-2006 Technical conditions of salt spray test chamber

8)GBT 20121-2006 / ISO11474-1998 Corrosion of metals and alloys - corrosion tests in artificial atmospheres - outdoor accelerated test under salt spray - scab test