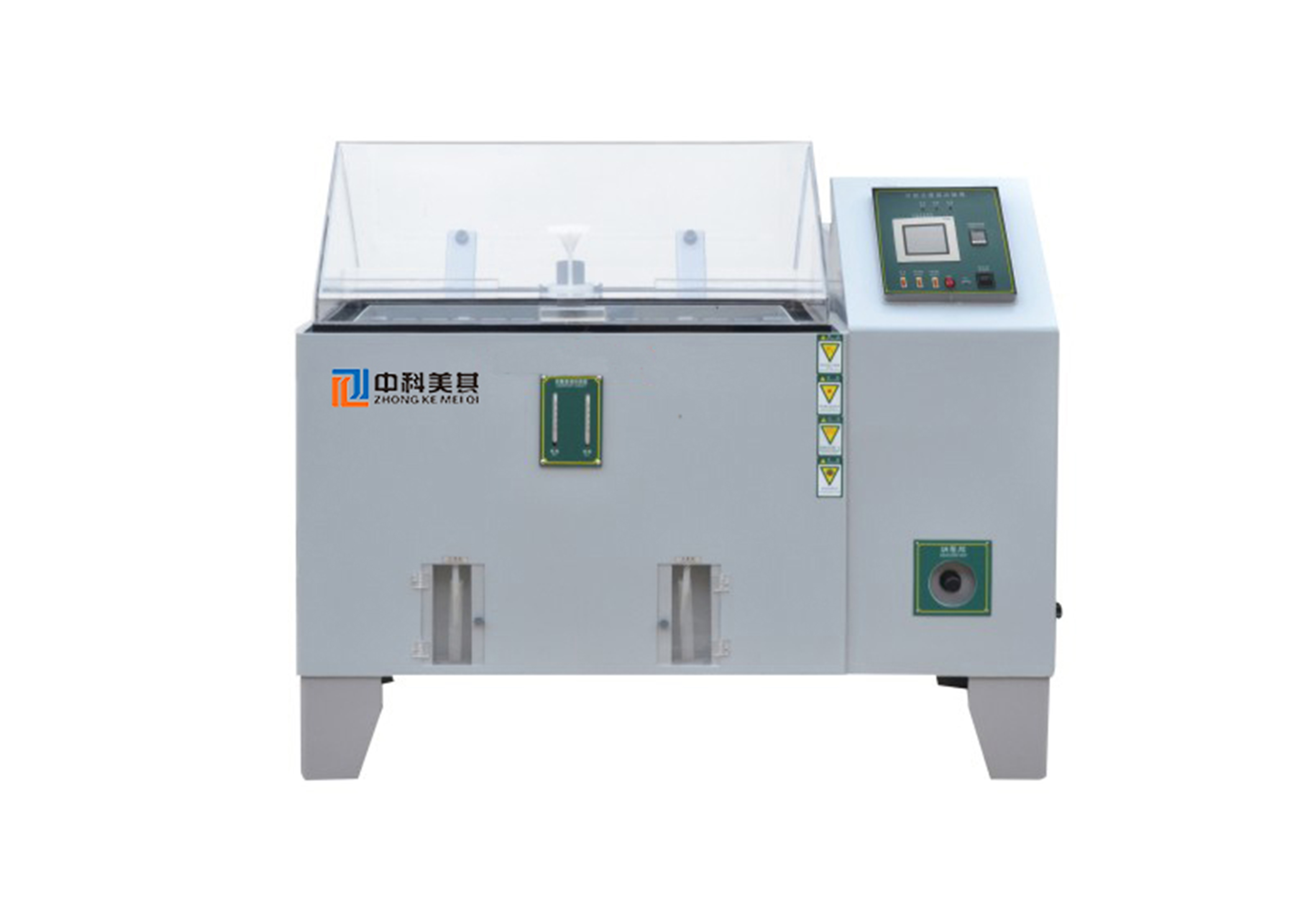

Model:MQ-YW-90

Product use:

It is suitable for salt spray corrosion test of electronic, electrical, automotive parts, hardware tools and other parts, metal materials and products coating.

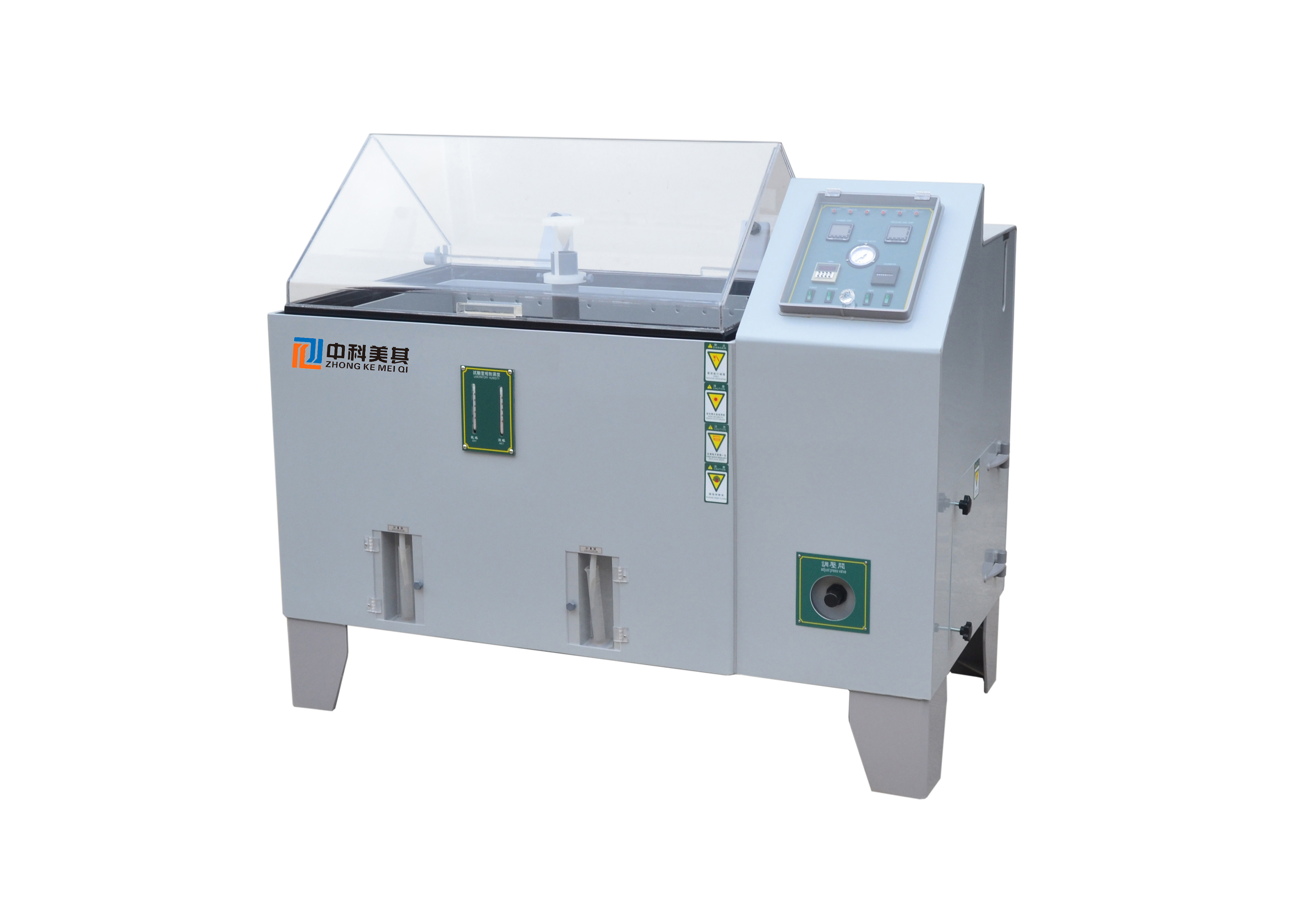

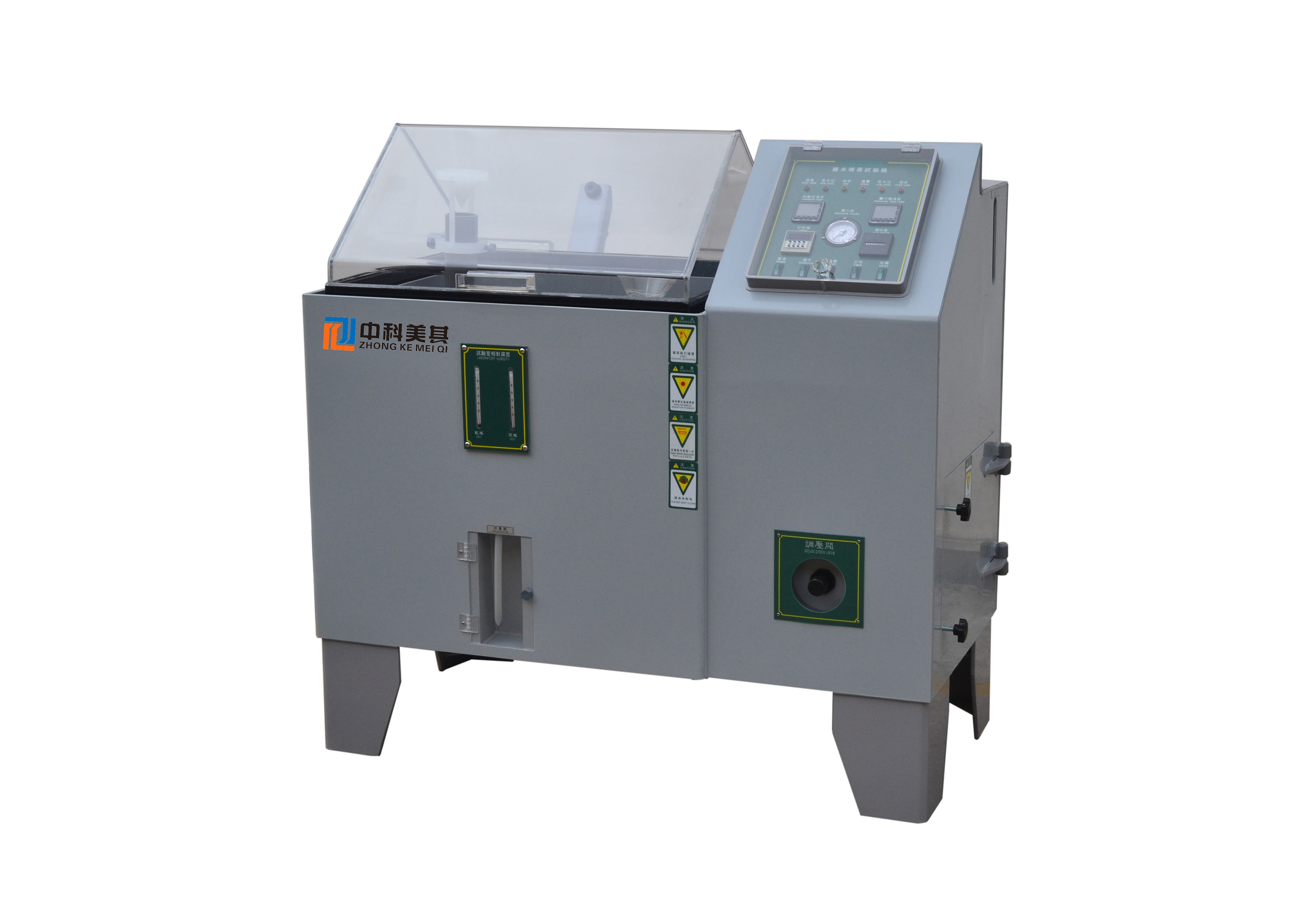

Product structure features:

Both inside and outside the studio are made of anticorrosive materials, which have the characteristics of light weight, high strength, no leakage, flat surface, smooth and easy to clean.

The water seal salt fog does not leak, the jacket air duct is heated, causes the studio to heat up quickly, the temperature distribution is uniform;

Tower spray, the spray material is small, and the natural deposition distribution of salt fog is uniform.

The control system is easy to operate, PID self-tuning digital display instrument, with over-temperature protection;

Salt Spray Test Chamber

Parameters

|

Product Name |

Salt Spray Test Chamber |

|||||

|

Product Model |

MQ-YW-60 |

MQ-YW-90 |

MQ-YW-120 |

MQ-YW-160 |

MQ-YW-200 |

|

|

Volume(L) |

108 |

270 |

480 |

800 |

1440 |

|

|

Internal Size W×H×W(mm) |

600×400×450 |

900×500×600 |

1200×500×800 |

1600×500×1000 |

2000×600×1200 |

|

|

External Size W×H×W(mm) |

1150×1090×672 |

1450×1200×842 |

2080×1285×1240 |

2480×1520×1450 |

2900×1550×1650 |

|

|

Performance Index |

Temperature Range |

Laboratory Temperature Range :RT~50℃ Saturated air barrel Temperature Range :RT~63℃ |

||||

|

Temperature Deviation |

±1.0℃ |

|||||

|

Temperature Uniformity |

≤2.0℃ |

|||||

|

Temperature Fluctuation |

±0.5℃ |

|||||

|

Heating Rate |

Test Room RT→+50℃≤60 min Pressure Barrel RT→+63℃≤60 min |

|||||

|

Salt fog deposition |

1~2ml/80㎡ (At least 16 hours were collected and averaged) |

|||||

|

Spray Pressure |

70~170Kpa |

|||||

|

Spraying Mode |

Continuous spray |

|||||

|

Test time |

1~999(S、M、H)adjustable |

|||||

|

PH |

6.5~7.2 3.0~3.2 |

|||||

|

Main Part |

Control System |

LCD touch screen temperature controller |

||||

|

PT100 thermocouple (armor), PID control |

||||||

|

Spraying System |

The Nozzle is made of special glass material, the size and angle of spray can be controlled |

|||||

|

operate manual spray or set automatic spray according to program |

||||||

|

Structural Features |

Material Enclosure |

Imported PVC polyethylene board is adopted

|

||||

|

Medicament refill cylinder |

hidden type supplementary water gauge

|

|||||

|

Pressurized air drum |

SUS304# stainless steel high-pressure barrel |

|||||

|

Test Rack |

The plane indexing frame can be used to adjust the Angle of fog falling or being foggy at any direction |

|||||

|

Cover Material |

imported European acrylic board

|

|||||

|

Spray Tower |

air atomizing nozzle, height can be adjusted |

|||||

|

Spray volume collector |

Cone funnel with diameter of 100mm

|

|||||

|

Heating System |

Titanium alloy heat pipe, steam heating, P.I.D. control heating |

|||||

|

Brine Tank |

Made of PVC board |

|||||

|

Saturated air barrel |

SUS304 Stainless |

|||||

|

Drain line |

acid and alkali resistant PVC piping |

|||||

|

Heater |

Titanium alloy armored electric heating tube (test chamber bottom heating) SUS316# stainless steel armoured heating tube (saturation barrel) |

|||||

|

Standard Fittings |

1 set of nozzles, 2 fog collecting and measuring cylinders, 2 fog collecting collectors, etc |

|||||

|

Safty Device |

Leakage, short circuit, motor overheating, overload, over current protection |

|||||

|

Supply Voltage |

AC220V 50Hz |

|||||

|

Environment Requirement |

Temperature 5.0~+30.0℃,Humidity≤85%RH,Air Pressure 86Kpa~106Kpa |

|||||

Satandard Compliance :

1)GB/T2423.17-2008/IEC 60068-2-11 Test method for salt spray

2)ASTM.B117-2009 Test method for salt spray

3)JIS H8502 Test method for saline spray

4)GB/T10125-2012/ISO 9227-2006 Test method for saline spray

5)GB-T5170.8-2008 Test method for environmental test equipment for electrical and electronic products - salt spray test equipment

6)GB-T5170.11-2008 Test method for corrosive gas test equipment

7)GB-T10587-2006 Technical conditions of salt spray test chamber

8)GBT 20121-2006 / ISO11474-1998 Corrosion of metals and alloys - corrosion tests in artificial atmospheres - outdoor accelerated test under salt spray - scab test